Study on Evaluating the EMI Filter for Electronic Communication Fans

- DOI

- 10.2991/jrnal.k.211108.008How to use a DOI?

- Keywords

- Electronically commutated fan; electromagnetic compatibility; digital control strategy

- Abstract

An electronically commutated fan has a complex digital control mode compared to the conventional alternating current fans. Since a serious electromagnetic compatibility situation occurs in the electronic commutation fan system, the filter circuit and mechanical design of a fan system are very important. A digital control strategy for a fan was designed to reduce the component of the electromagnetic interference filter, therefore the suppression of conducted and radiated electromagnetic interference will be achieved in the proposed fan system. Moreover, the proposed fan integrates the mechanical design to solve the problems of radiated electromagnetic interference. A single-phase Brushless DC Electric Motor (BLDC) driver is designed and constructed. Finally, the electromagnetic interference that occurred in the proposed fan is analyzed and the suppression strategy is provided. The experiment verification for the electronically commutated fan is presented.

- Copyright

- © 2021 The Authors. Published by Atlantis Press International B.V.

- Open Access

- This is an open access article distributed under the CC BY-NC 4.0 license (http://creativecommons.org/licenses/by-nc/4.0/).

1. INTRODUCTION

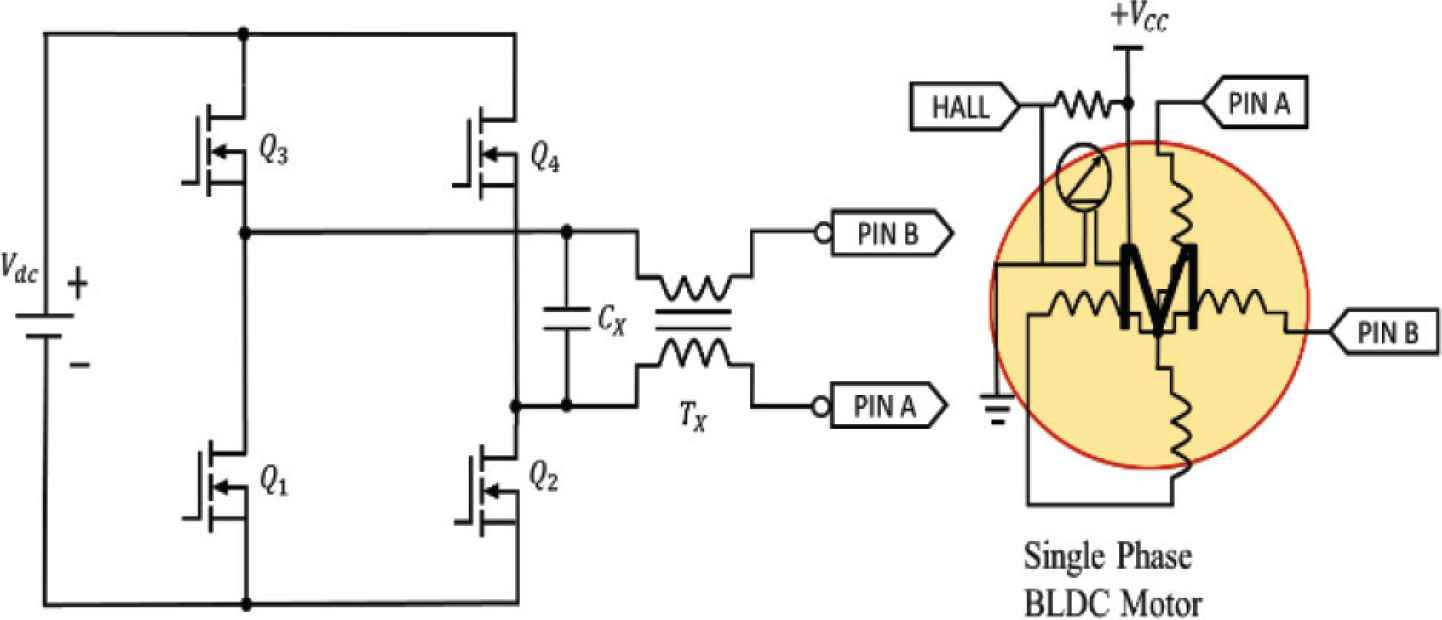

The electronic communication fan combines the frequency conversion function, and the power transistors for frequency modulation to achieve speed control. Because of the higher speed, the motor output efficiency is improved. The Single-Phase BLDC motor system is driven by an AC power supply. A DC motor is used for this system, so the friction loss is reduced. The advantages of AC and DC fans are combined to improve the efficiency and life of the electronic commutation fan. Figure 1 shows the circuit topology of a commercial electronic commutation fan. Several switch devices were switched at high speed, and the voltage and current are changed at the same time. The result not only causes more serious electromagnetic interference problems [1,2] but also affects the electromagnetic tolerance of the internal controller. Therefore, the production design has to be considered for passing relevant electromagnetic compatibility certification.

Single-phase BLDC motor driver schematic diagram.

2. EMI STANDARD FOR ELECTRONIC COMMUNICATION SYSTEM

Generally speaking, the tests of electromagnetic compatibility are divided into two types: Electromagnetic Interference (EMI) and electromagnetic susceptibility [3,4]. The EMI testing refers to measure of the intensity of conductive interference and radiant interference while the electronics device is normally operated during the testing procedure. The purpose of electromagnetic interference suppression design is to reduce the intensity of noise generated by the electronics device under testing, and it was not to affect other electronic products in the test environment. On the contrary, the purpose of electromagnetic tolerance is to prevent the device under test (DUT) from being interfered with by other electronic products in the environment during operations.

There are international standards for the electromagnetic interference law of electronic communication fans, which can refer to the European regulations EN 55011, the United States FCC PART 18, and the domestic CNS 13803. Among them, there are two different limit values of class A and B according to the type of this product, which is either commercial or residential households. However, the product analysis in this paper will be used in information products since Europe is the main market. So, the information products for European standards will be adopted. Class B electromagnetic interference standards in EN55022, EN55022, and EN55011 are the same as for Class B electromagnetic interference test standards.

3. EMI SUPPRESSION AND ANALYSIS OF ELECTRONIC COMMUNICATION SYSTEM

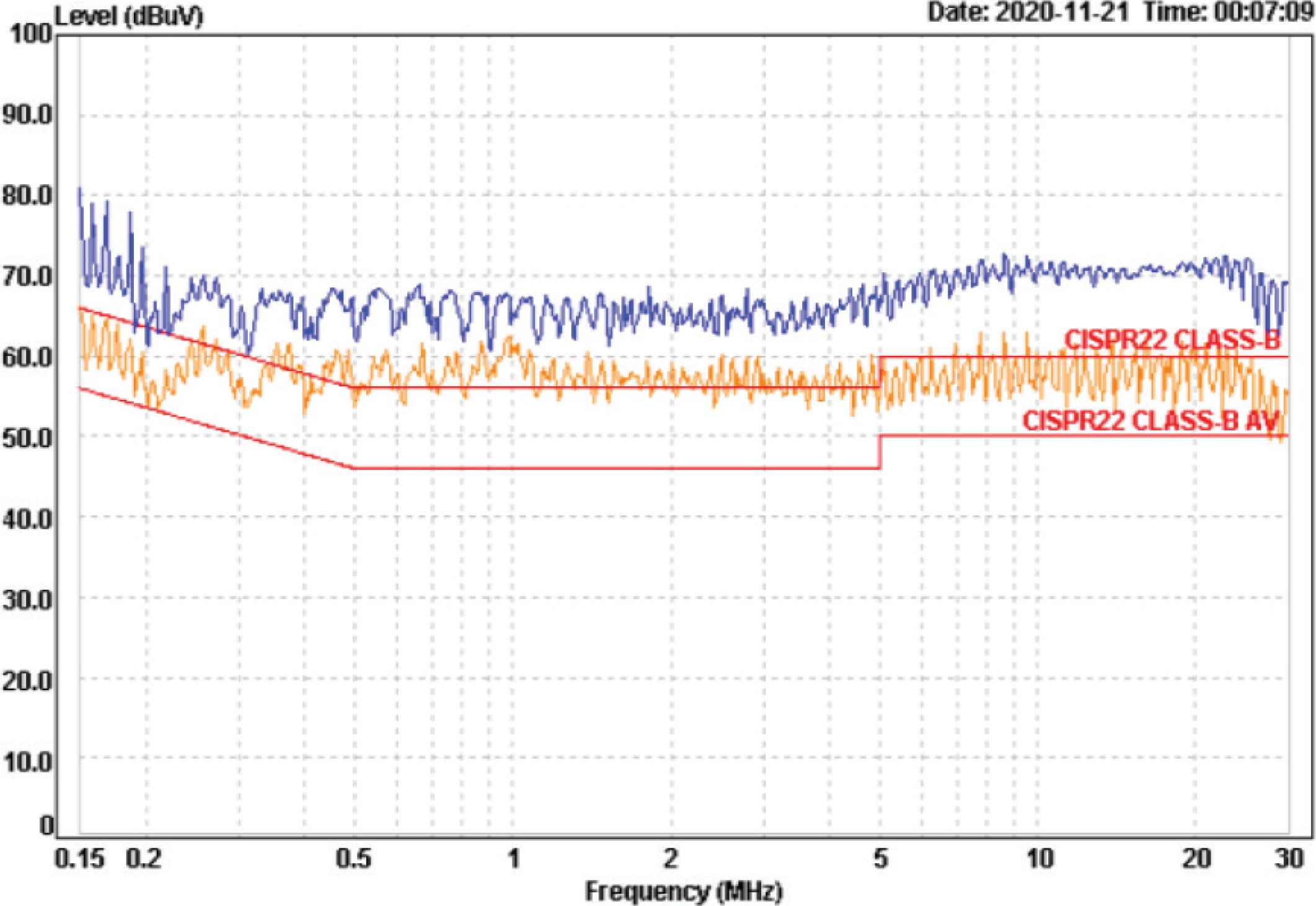

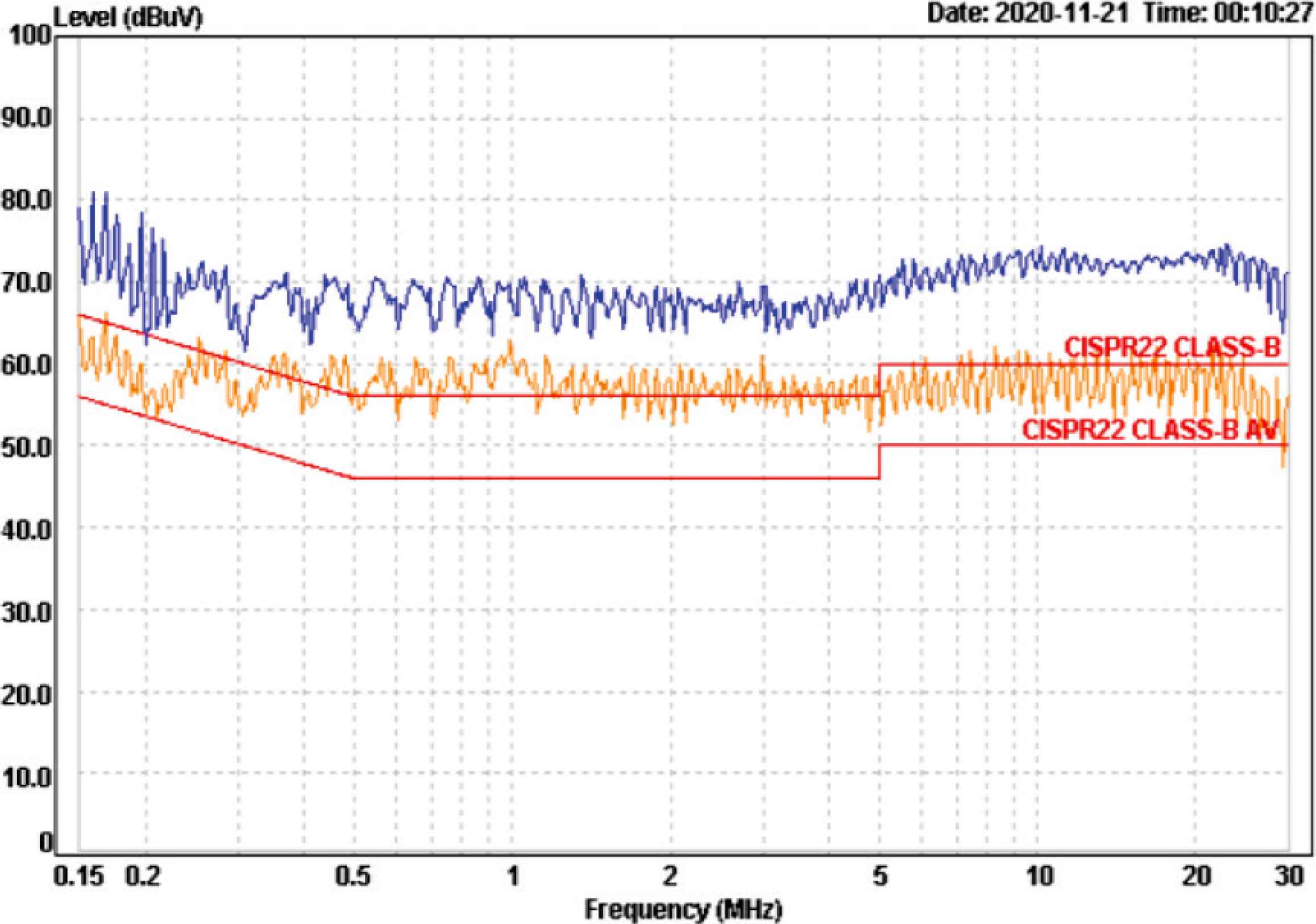

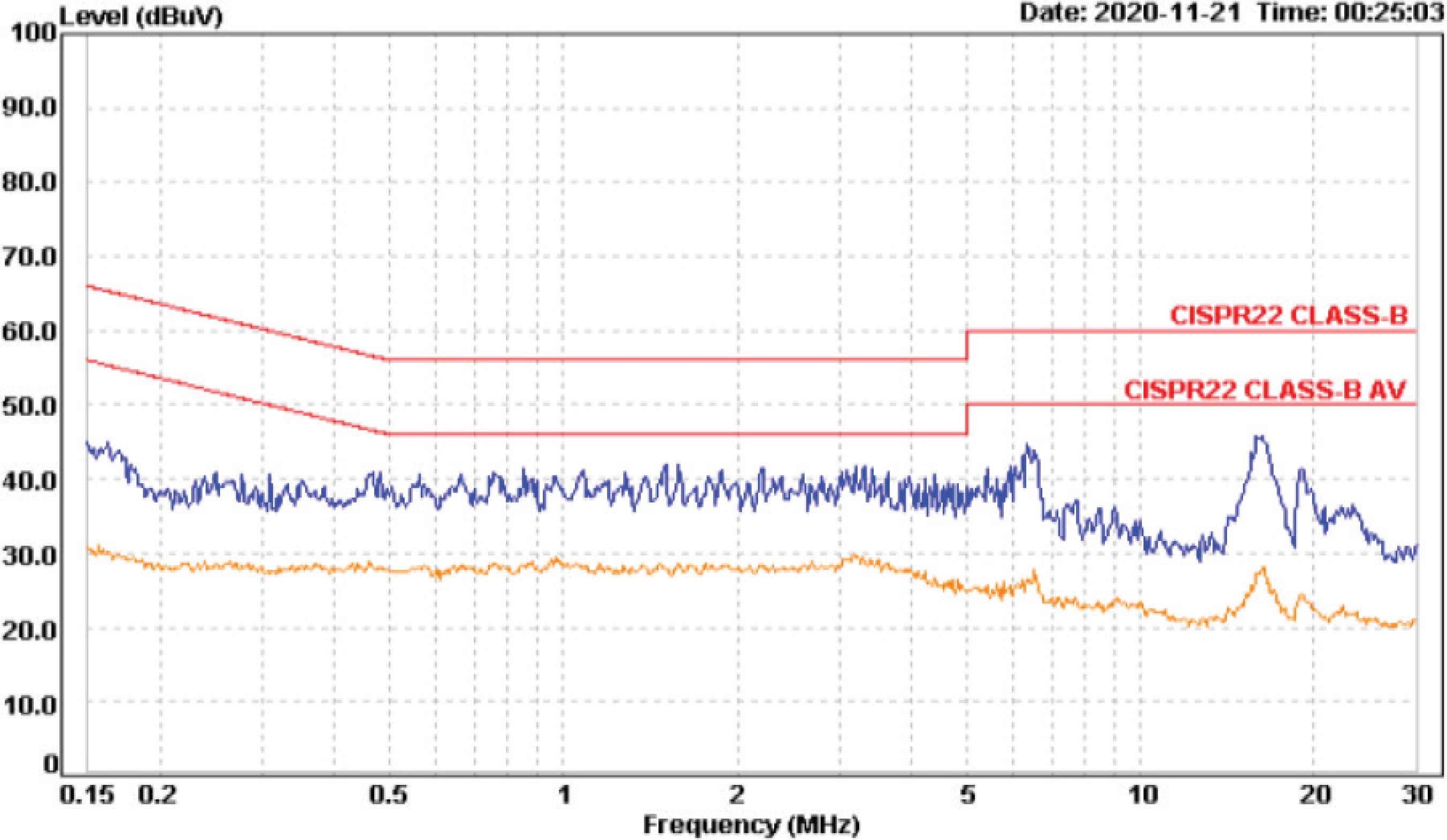

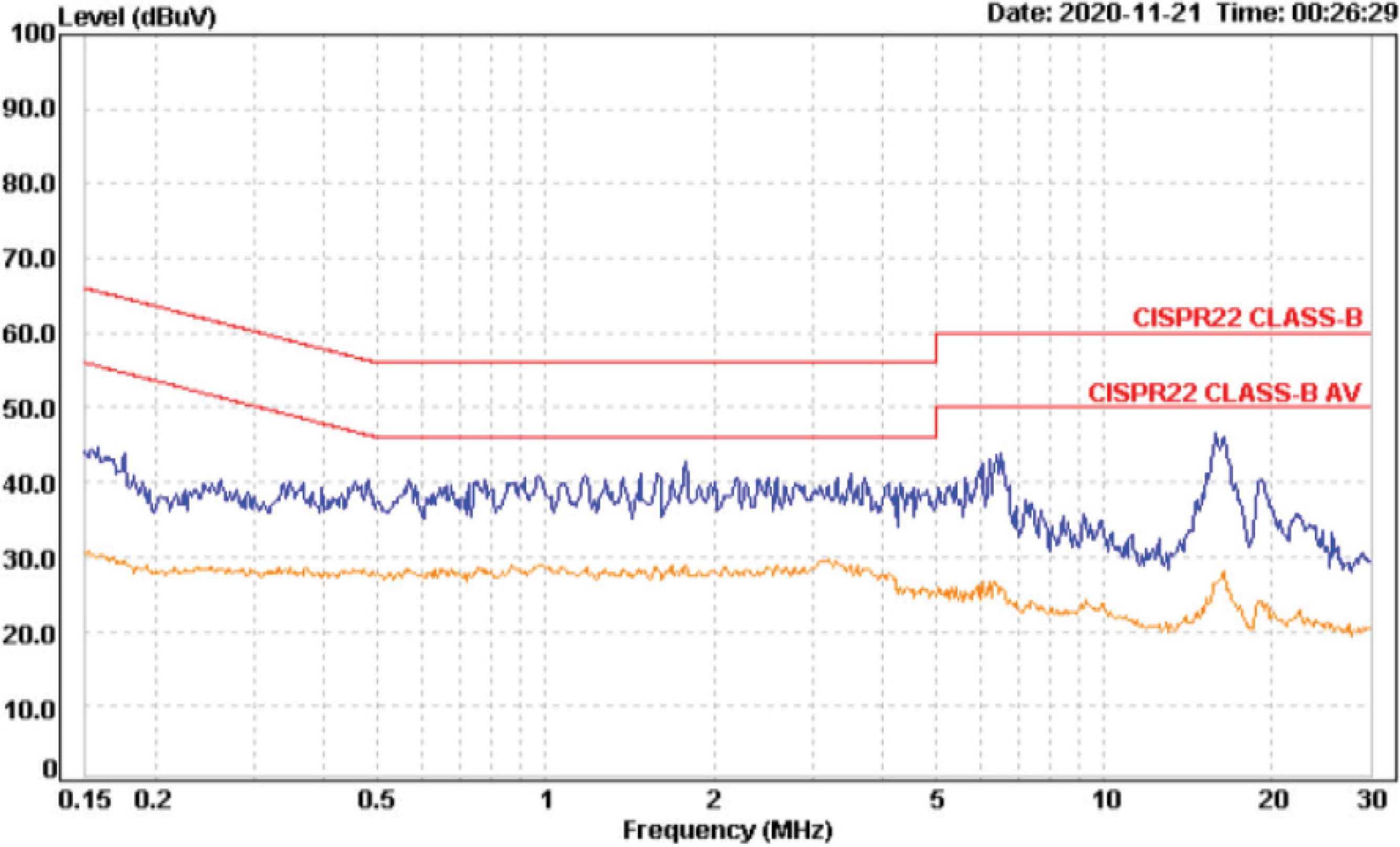

3.1. Conduction EMI Measurement

To measure the noise values of the live wire (Line, L) and the neutral wire (Neutral, N) after a connection of the line impedance stabilization network (LISN). The measured results are shown in Figures 2 and 3. Observing the two figures, it can be seen that the test value without any filter and other countermeasures far exceeds the standard limit value.

EMI testing of L phase conductivity.

EMI testing of N phase conductivity.

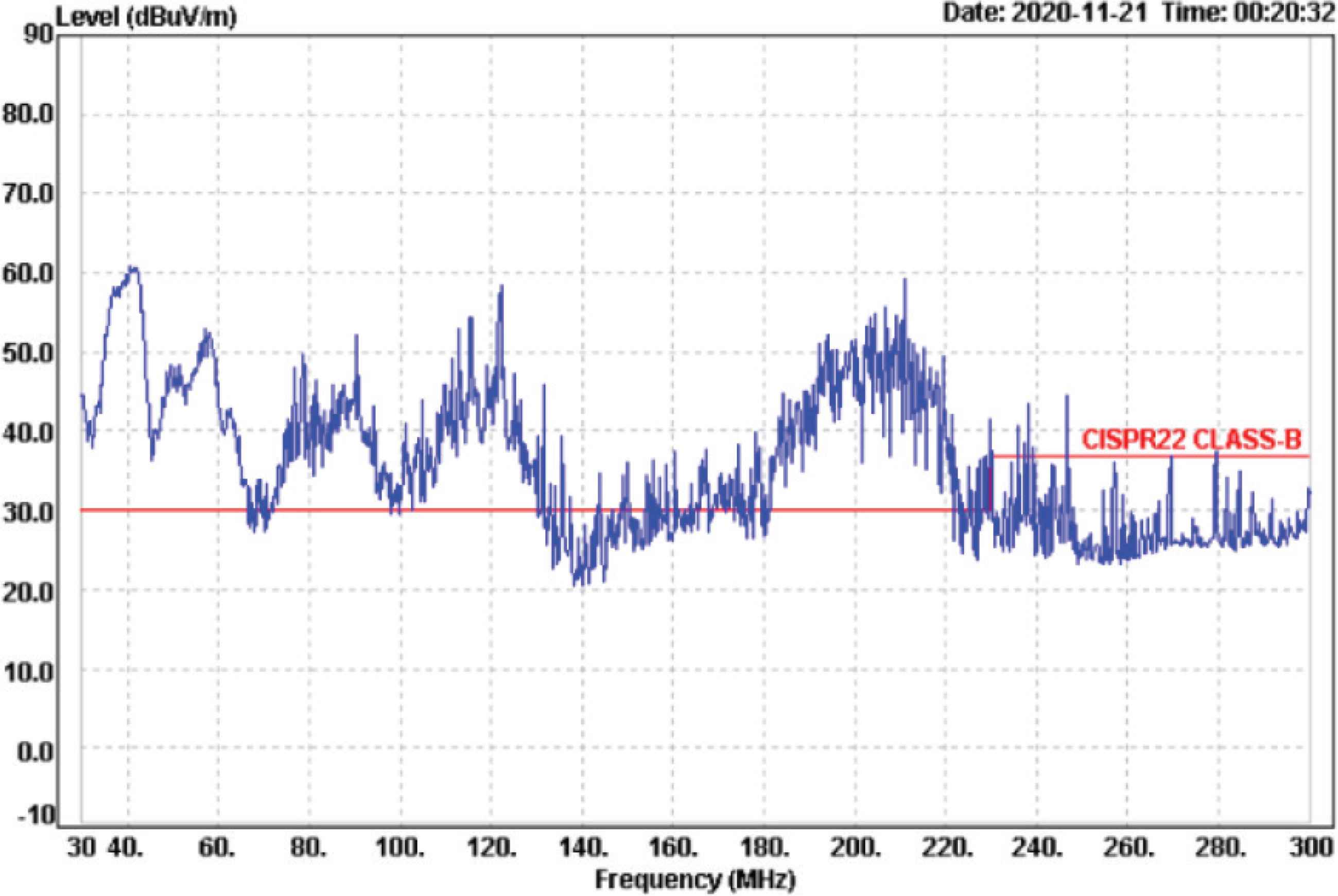

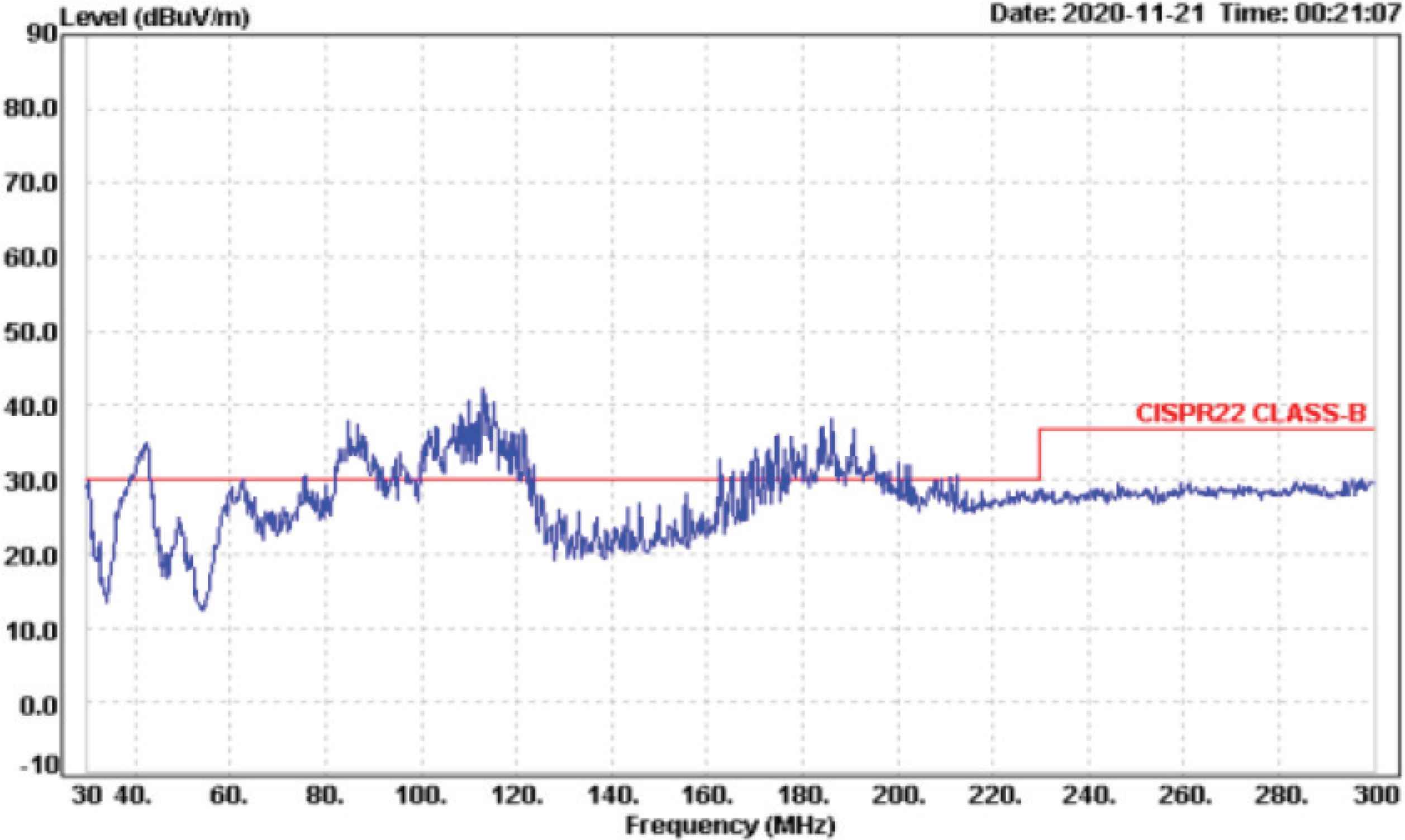

3.2. Radiation EMI Measurement

According to the above section, the noise measurement of the EUT was received through the antenna under two different polarities, vertical and polar. The actual test diagrams are shown in Figures 4 and 5. It can also be seen that the noise radiated through space is very serious.

The vertical polarity test of radiation EMI.

The horizontal polarity test of radiation EMI.

3.3. The Suppression Strategy for Conduction EMI and Radiation EMI

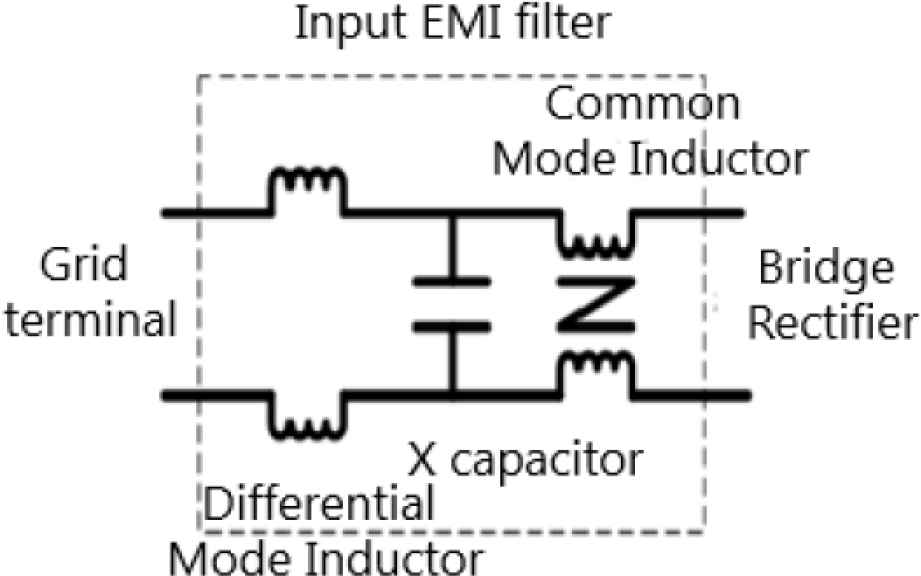

3.3.1. A strategy of conduction EMI

Conducted EMI is mainly used to measure the noise transmitted by the power line through LISN, so the main suppression method is to add an EMI filter to the power line [5]. However, it can be seen that a multi-stage filter with grounding is required to have a wider suppression range from Figure 2. In this paper, the space of the DUT is limited, and there is no ground wire architecture. The input EMI filter architecture of the electronic commutation fan systems is show in Figure 6. The differential mode inductance is 100 µH, the X capacitor is 0.1 µF, and the common-mode inductance is 20 mH.

Input EMI filter structure.

With the advantage of digital control, Spread Spectrum [6–9] is added to suppress the interference problem caused by the main operating frequency.

where N is the harmonic number

δ is spread spectrum

fc is switching frequency

fm is frequency modulation

Figures 7 and 8 show the actual test patterns after adding the input EMI filter and other countermeasures to the EUT internal circuit.

EMI testing of L phase conductivity after the suppression.

EMI testing of N phase conductivity after the suppression.

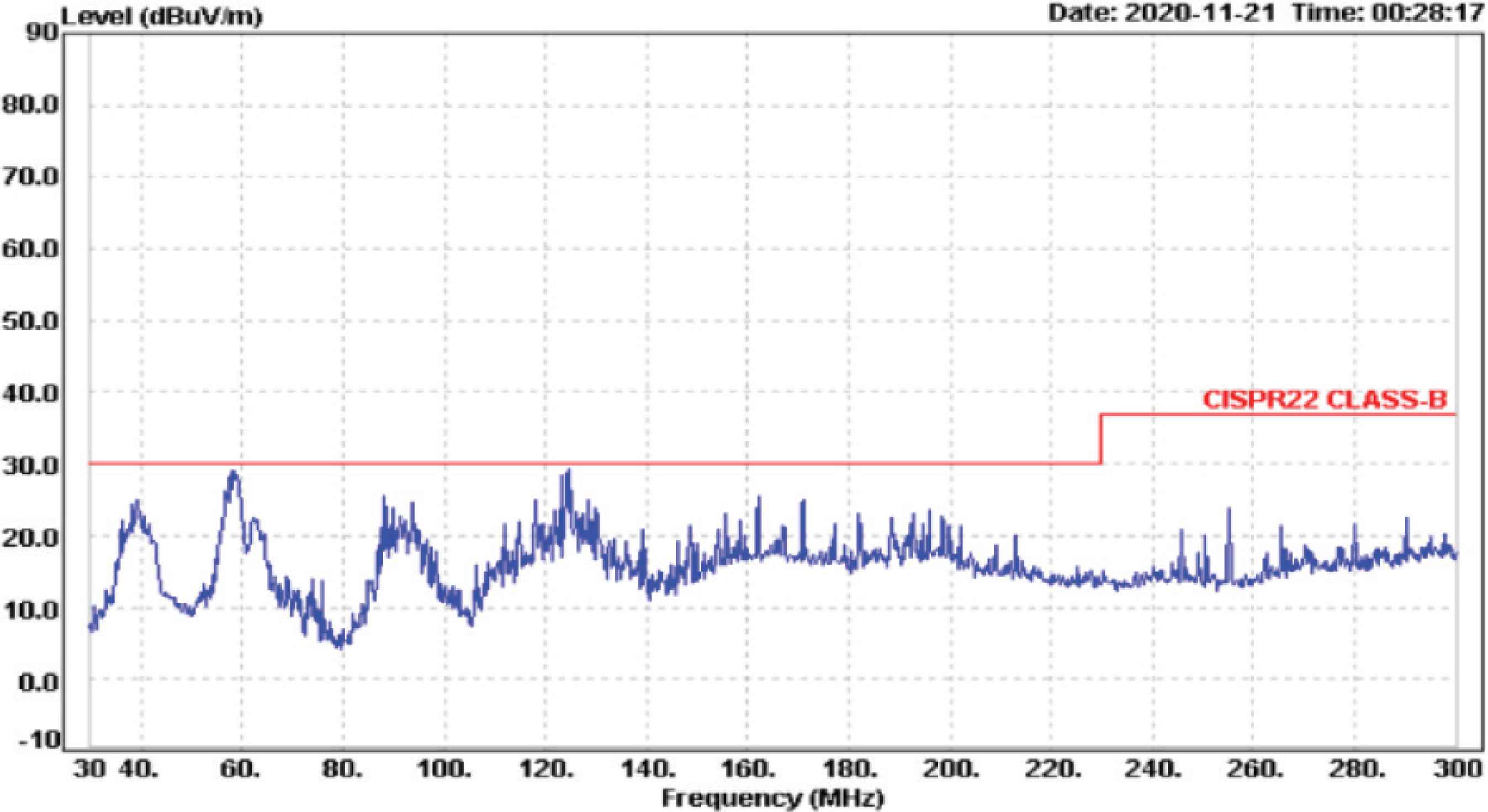

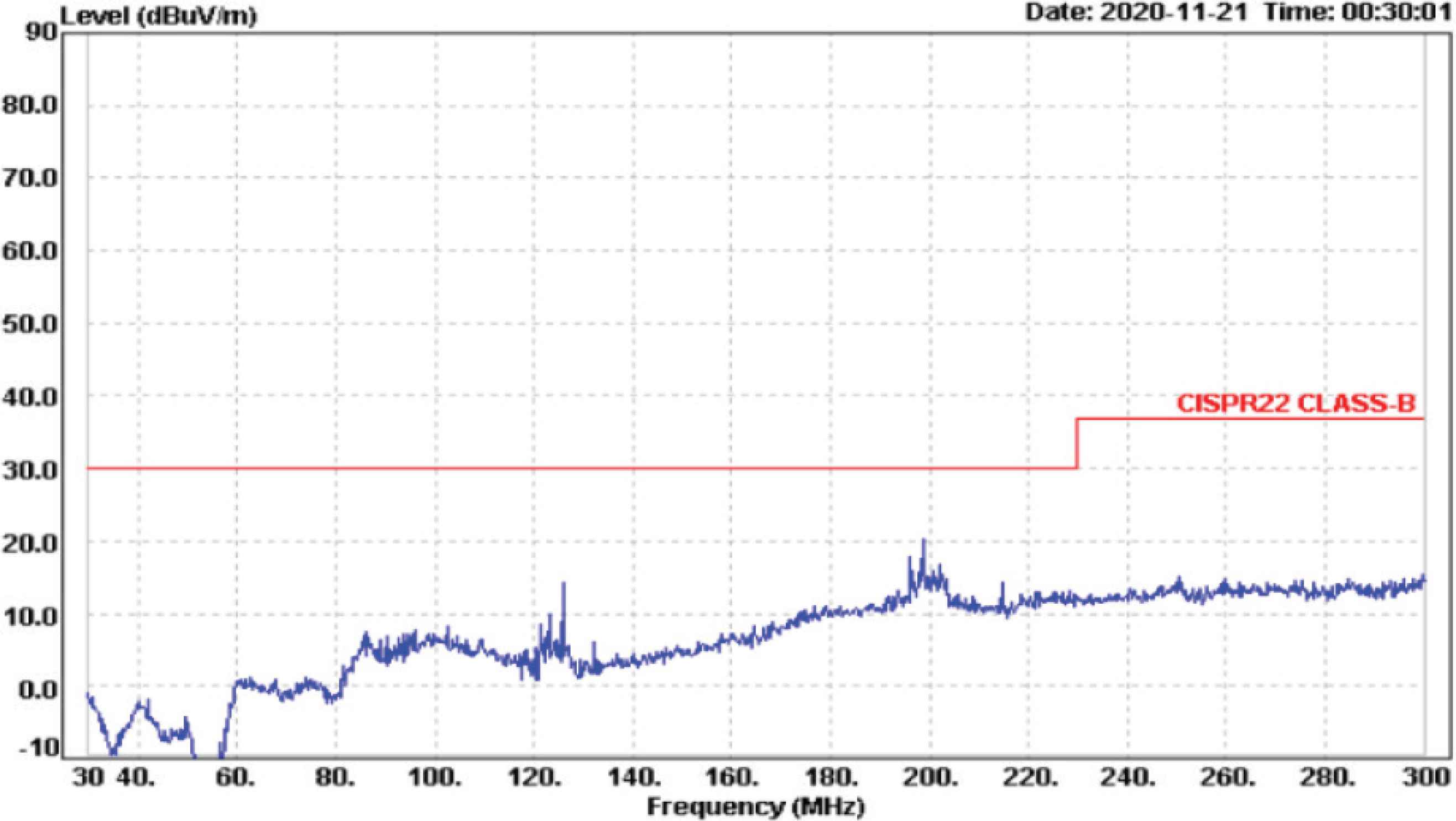

3.3.2. A strategy of radiation EMI

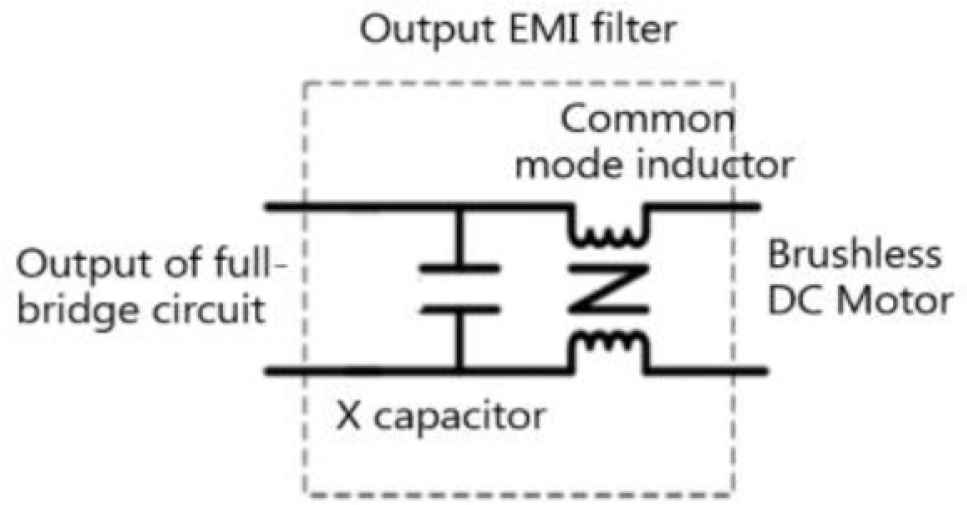

To solve the radiation problem between the circuit output and the motor, an output EMI filter design is required for the electronic commutation fan systems. The common-mode inductance is 0.95 mH and the X capacitor is 4700 pF. Both the useful safety certified components, as shown in Figure 9.

Output EMI filter structure.

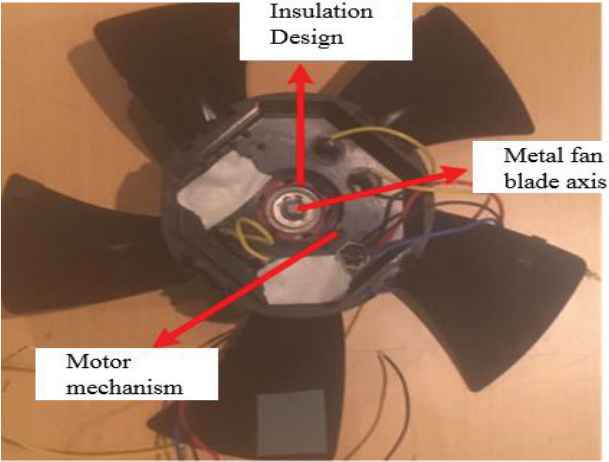

The proposed EUT has two types, namely plastic fan blades and metal fan blades. Among them, the series of metal fan blades have the most serious radiated EMI problem. The noise generated by the drive motor will provide a path to the metal fan blade through the metal shaft, which results in a serious antenna effect. Therefore, an insulating part will be added to the mechanism part, as shown in Figure 10, which not only saves the cost of motor manufacturing but also solves the problem of radiated EMI. Figures 11 and 12 show the actual test patterns after EUT suppression.

A strategy for motor shaft and mechanism insulation design.

The vertical polarity test of radiation EMI after the suppression.

The horizontal polarity test of radiation EMI after the suppression.

4. CONCLUSION

This paper has proposed an electronic commutation fan to perform the practical electromagnetic interference certification process for the EUT. The suppression of conductive EMI and radiate EMI was discussed, and a digital control system was designed to reduce the EMI filter components in this research. Meanwhile, the proposed system combines the proper mechanism to solve the problem of serious radiated EMI caused by the system operating without grounding. This method can not only be applied for this product, but also other relative products producing a similar effect. The saving of time and cost will be implemented after a successful certification of the subsequent relative products.

CONFLICTS OF INTEREST

The authors declare they have no conflicts of interest.

ACKNOWLEDGMENTS

The research described in this paper was supported by the Ministry of Science and Technology, the Republic of China (Grant. No. 109-2221-E-150-041-MY3). The authors are indebted to the people at Computer Science and Information Engineering, The National Taiwan University of Science and Technology, for their help in providing the research data of the instrument equipment.

AUTHORS INTRODUCTION

Asst. Prof. Ching-Chun Chuang

He received a PhD degree in Electronics Engineering from the National Taiwan University of Science and Technology, Taiwan, in 2013. Since 2017, he has been an Associate Professor at Computer Science and Information Engineering, Formosa University, Taiwan. His research interests include Power Electronics, Digital Control, IoT Applications, and Robot Applications.

He received a PhD degree in Electronics Engineering from the National Taiwan University of Science and Technology, Taiwan, in 2013. Since 2017, he has been an Associate Professor at Computer Science and Information Engineering, Formosa University, Taiwan. His research interests include Power Electronics, Digital Control, IoT Applications, and Robot Applications.

Prof. Chih-Chiang Hua

He (S’91–M’92) received the B.S. degree in Electrical Engineering from National Cheng Kung University, Tainan, Taiwan, in 1984, and the M.S. and PhD degrees in Electrical Engineering from the University of Missouri, Columbia, MO, USA, in 1990 and 1992, respectively. Since 1992, he has been with the National Yunlin University of Science and Technology, Douliou, Taiwan, where he is currently a Professor at the Department of Electrical Engineering. His research interests include Power Electronics Converters, Uninterruptible Power Supplies, and Photovoltaic/Wind Energy Systems. He is a member of the IEEE Power Electronics and the IEEE Industrial Electronics Societies.

He (S’91–M’92) received the B.S. degree in Electrical Engineering from National Cheng Kung University, Tainan, Taiwan, in 1984, and the M.S. and PhD degrees in Electrical Engineering from the University of Missouri, Columbia, MO, USA, in 1990 and 1992, respectively. Since 1992, he has been with the National Yunlin University of Science and Technology, Douliou, Taiwan, where he is currently a Professor at the Department of Electrical Engineering. His research interests include Power Electronics Converters, Uninterruptible Power Supplies, and Photovoltaic/Wind Energy Systems. He is a member of the IEEE Power Electronics and the IEEE Industrial Electronics Societies.

Prof. Chung-Wen Hung

He received the PhD degree in Electrical Engineering from National Taiwan University in 2006. Currently, he is a Professor in National Yunlin University of Science & Technology. His research interests include IoT, IIoT, Power Electronics, Motor Control, and AI Application.

He received the PhD degree in Electrical Engineering from National Taiwan University in 2006. Currently, he is a Professor in National Yunlin University of Science & Technology. His research interests include IoT, IIoT, Power Electronics, Motor Control, and AI Application.

Dr. Chun-Jen Yao

He (1980) received a PhD degree in Electronics Engineering from the National Taiwan University of Science and Technology, Taiwan, in 2010. Since 2017, he has been a Postdoctoral Research Fellow at Electronics Engineering, National Taiwan University of Science and Technology, Taiwan. His research interests include Electromagnetic Compatibility, Power Electronics and Digital Control.

He (1980) received a PhD degree in Electronics Engineering from the National Taiwan University of Science and Technology, Taiwan, in 2010. Since 2017, he has been a Postdoctoral Research Fellow at Electronics Engineering, National Taiwan University of Science and Technology, Taiwan. His research interests include Electromagnetic Compatibility, Power Electronics and Digital Control.

REFERENCES

Cite this article

TY - JOUR AU - Ching-Chun Chuang AU - Chih-Chiang Hua AU - Chung-Wen Hung AU - Chun-Jen Yao PY - 2021 DA - 2021/12/27 TI - Study on Evaluating the EMI Filter for Electronic Communication Fans JO - Journal of Robotics, Networking and Artificial Life SP - 269 EP - 272 VL - 8 IS - 4 SN - 2352-6386 UR - https://doi.org/10.2991/jrnal.k.211108.008 DO - 10.2991/jrnal.k.211108.008 ID - Chuang2021 ER -